2025- 06- 09

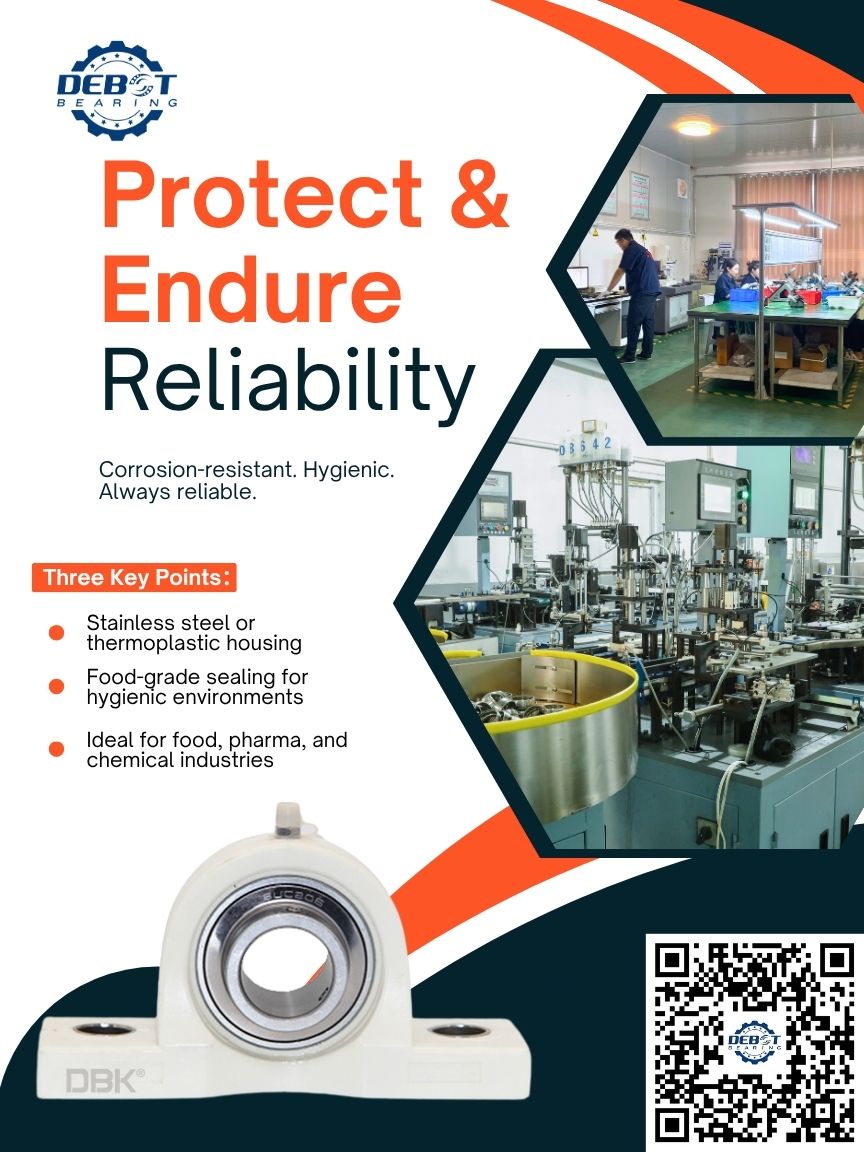

In industries such as food processing, pharmaceuticals, and chemicals, bearing units must offer more than just strength—they need to meet strict hygiene and corrosion resistance standards. That’s exactly what the SS-UCPPL200 series from DEBOT delivers.

This series includes both stainless steel and thermoplastic housing options. The stainless steel models—built with AISI 304 or 316—are ideal for environments with moisture, salt, or chemical exposure, offering excellent corrosion resistance and load capacity. Thermoplastic housing units, on the other hand, are lightweight, non-corrosive, and easy to clean—perfect for hygienic applications like food and beverage lines or sterile environments.

Both versions are equipped with food-grade seals to prevent contamination, reduce downtime, and extend the lifespan of your equipment.

● Superior Corrosion Resistance: With stainless steel or thermoplastic construction, these units stand up to moisture and chemicals.

● Hygienic Design: Smooth, sealed surfaces ensure compliance with strict sanitary standards.

● Versatile Applications: Suitable for food, pharma, marine, and chemical industries.

● Customizable Options: Available in various sizes and sealing configurations for tailored needs.

Whether your priority is cleanliness, durability, or corrosion resistance, the SS-UCPPL200 series provides a robust solution for critical environments.